Long lead times for customer quotes were seen as a capacity problem, but were in fact a flow problem. Joacim Harrby shares the story of how one company moved from frustration and unpredictable waiting times to fast customer feedback, reduced employee stress, and improved performance metrics, without increasing the pace.

Peter remembers exactly when the situation was no longer manageable. An important customer called and asked when the quote would be sent. His honest answer was, “I have no idea.” The customer replied, “We need an answer today, otherwise we will move on to someone else.” Then he hung up. It was not the first time.

Peter worked as an Operations Manager at a business in central Stockholm, where the pace was constantly high. With offices in three countries, several systems, and many people involved, expectations from management were clear: respond faster. Customers no longer accept waiting. At the same time, there was no clear answer to how long a quote should take, and even less understanding of why it took so long.

A typical day looked like this. Requests came in, were started, paused, someone was missing information, someone was waiting for a response, someone did not know who owned the work item. Each time a quote was delayed, Peter felt frustration. The team worked hard, sometimes late into the evening and often in parallel with several complex issues. Still, they lost business. What hurt most was that customers did not experience their effort, only the waiting.

The symptoms, high speed, low stability

One afternoon, Peter stayed late at the office when he heard Jenny, who was responsible for project planning, sigh deeply. He walked over to her.

“Look at this,” she said. “You’ve been pushing us for faster customer responses. Management talks about lead times. But how am I supposed to work with this?”

She turned the screen toward him to show the material she had just received from one of the sales reps, Johan. “What does Johan’s information mean? Who is responsible for it? What should I promise the customer tomorrow? Do you think this is good input?”

Peter understood the problem. It was not about working faster, it was about the quality of what was handed over.

“You’re right,” he said. “This won’t be finished tonight. Tomorrow we’ll go to Johan together and start there.”

That evening he went home with more curiosity than frustration. What had looked like a capacity problem was something else. After a few calls to the IT department to gather more data, the pattern began to emerge, largely thanks to Jenny’s observations about the input from sales. He realized this could become truly important for the entire organization.

Mobilizing the team to take action

The next day, Peter gathered the sales and planning departments for a short meeting. He announced that the improvement effort would now be intensified and asked everyone to clear their calendars for the following Thursday for a joint workshop. The focus would be on reviewing their ways of working and how they together could improve response times. In the meantime, Jenny and Johan were asked to immediately discuss the quote for the customer and resolve any issues with missing information.

Peter’s insight from the night before was that what looked like a capacity problem to everyone was actually a flow problem. With experienced staff and systems such as Outlook, Excel, Jira, and local tools, information moved between people and systems, but was it the right information at the right time?

Visualizing and tracking every flow

The following Thursday, the improvement work began with Jenny and Johan’s issue. “Let’s follow a work item from start to finish,” Peter said.

The team mapped out the course of the customer case from the previous week. They listed all activities, timestamps, and responsible parties. Once they visualized the sequence of events, they were surprised. It was a chaos of handovers and queues, and a job everyone thought was simple had taken seven days.

This sparked a strong desire to understand more. They began comparing fast and slow cases. What was the difference?

The teams brought the insights from Peter’s workshop into their daily work. At first, they assumed it was about complexity, that large customers required more special solutions. Over the following weeks, they registered every work item and tracked each flow unit to see what patterns emerged. Using software, they visualized lead time and could see where time disappeared.

To their surprise, the difference did not lie in customer size or campaign scope. The decisive factor was the handover.

The link between handover quality and total lead time

When Jenny’s team, who checked availability and booked campaigns, had all the correct information, things moved quickly. The case flowed through. But when they needed additional input from the sales department, the flow stopped.

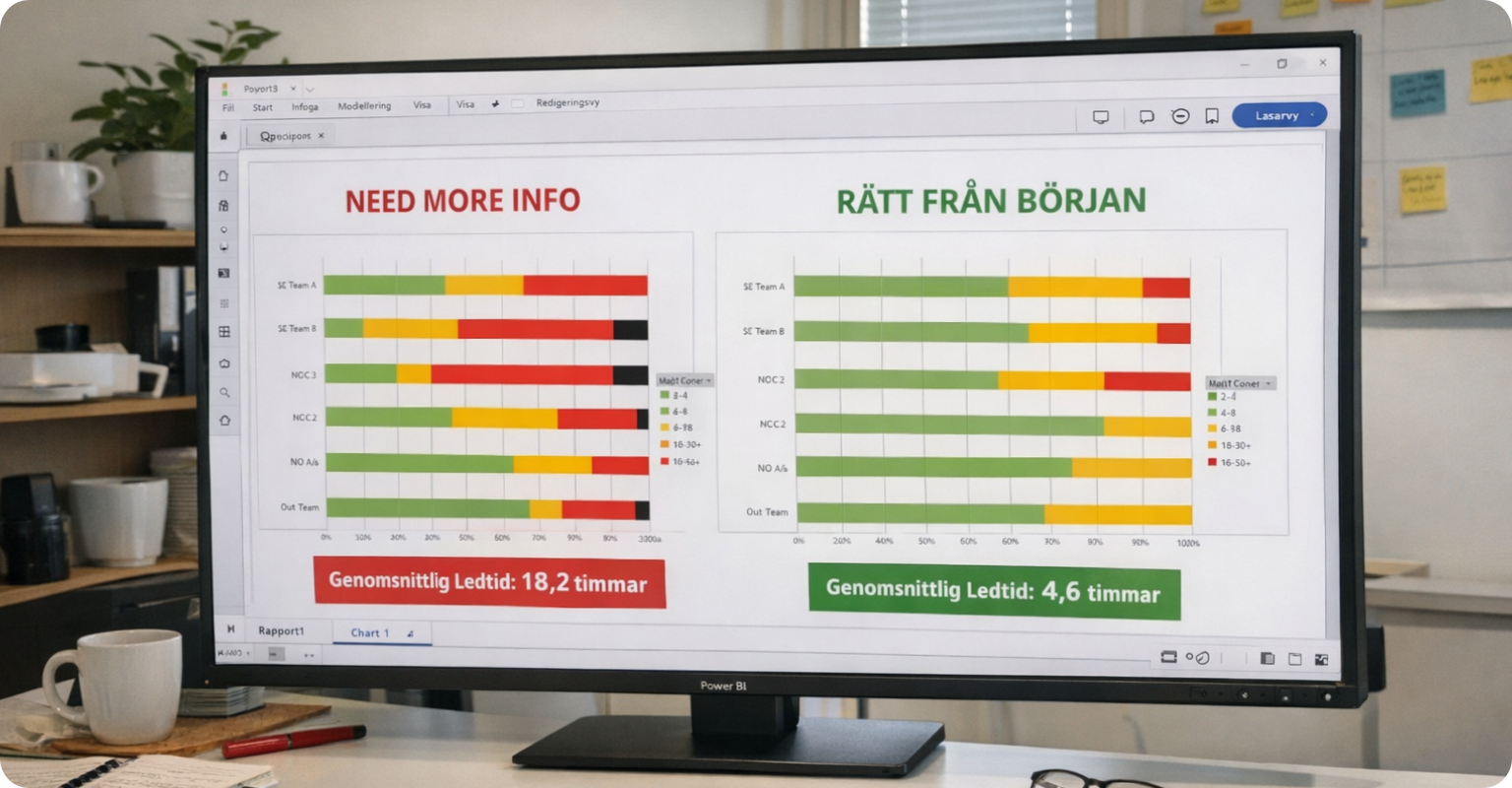

They labeled these cases: “Need more info.”

When they overlaid lead time data with this label, the result was clear. Cases that were correct from the start had short lead times, while those that required more information took significantly longer. This confirmed their shared effort to take a genuine interest in each customer case. Real customer focus, not just words.

Previously, it had been a challenge for planning to get the sales department to accept the problem. Discussions often got stuck in perceptions and defensiveness. But when they created the visualizations together, the link between handover quality and total lead time became clear. The charts showed that complete handovers dramatically reduced lead time, while incomplete handovers increased it significantly. The pattern was clear, and they had the power to change it. The problem was not slowness, but variation in quality.

Start asking the uncomfortable questions

To make the improvement work concrete in the project management tool Jira, Peter asked a simple question at an improvement meeting: “What is a good Jira?”

The answers were valuable. “This must be filled in,” Alice wrote. “This information is mandatory,” Fanny wrote. “This means a case is ready for the next step,” someone added. “This is a fully correct handover,” someone else concluded.

What had previously been unclear expectations became explicit criteria when the two teams collaborated. It was not about pointing fingers, but about defining a standard. “It was a bit uncomfortable and tentative,” Peter said afterward, “but mostly constructive.”

The results came without anyone having to run faster

As handover quality gradually became more stable, lead times decreased and the share of cases requiring additional information dropped. Variation was simply reduced.

The most interesting part? They did not hire more people. They did not increase the pace. They did not run faster. They did it right from the start.

Finally, they could promise customers answers the same day, often within a few hours. Customers noticed the difference. Employees felt less stress. Management saw improved performance metrics.

Getting things right beats speed every time

We often think speed is created by working faster, but in flows it is quality that creates pace. When handovers are right from the start, variation decreases, which leads to shorter lead times and increased competitiveness.

This applies regardless of industry or context: manufacturing, services, IT, media, public sector. The impact on lead time when quality is right is dramatic. Sometimes the greatest improvement is not to increase speed, but to ensure that we get it right every time.

Want to learn more?

Where in your organization does friction arise in handovers today, and how clearly is it defined what is complete and correct before work is passed on?

If you want to go deeper into how this works in practice, we are hosting a webinar on the topic.

Webinar: Handover Quality – The Foundation for Flow Efficiency

Webinar: Handover Quality – The Foundation for Flow Efficiency

Joacim Harrby walks through a step-by-step approach to improving internal cross-functional flow, with a clear focus on handover quality. You will:

• See a real improvement case from one of Hups’ customers

• Understand the problem, the solution, and the results

• Learn the theory behind flow efficiency in a way you can apply directly with your own team

This session is for leaders and practitioners who want continuous improvement to work across teams, not just within them.

March 5

Swedish session (13:00–14:00)

English session (15:00–16:00)