I've been researching about lean and operational excellence, and especially the Toyota Production System, for more than 20 years. There are a lot of interesting questions within this area. Today I'm going to elaborate a on the question - what is continuous improvement? What is the foundation of that philosophy?

One could argue that it's a method, but there are some founding principles behind continuous improvement that I would like to share. The first story came to me at a conference.

I was then in the board of directors of Lean Forum, which is a non-profit organization in Sweden. They are contributing to developing the concept of lean and spreading it to Swedish companies and organizations. Every year they have large conference, and this one took place approximately 15 years ago.

We had invited a legendary professor, namely Professor Jeffrey K Liker. He's the author of the bestselling book The Toyota Way and was “the Brad Pitt” of all lean conferences at that time. He gave a fantastic keynote speech, and I was lucky enough to have the opportunity to sit next to him at the following dinner.

He had so many stories to tell and between two of them, I said: “I have a question for you. You have been researching about lean for your whole career. You have such an extensive experience regarding what lean is, and especially the Toyota Production System. If you had to explain to me easily - what is lean?

I remember that he put down his knife and fork, looked at me and said: “I'm going to give you a story, that captures my view of what lean is”. And he told the story about a legendary Toyota Sensei named Oba-san.

The story about Oba-san

Toyota had been working with lean for many years at this time and were considered best in class, a role model within their industry. But they felt that there must be something more. What is the next step for us? Everyone said that if you want to understand lean, go to Toyota, have a company visit, talk with their top management. But they felt, of course we can spread our knowledge and inspire others, but we too want to take the next step.

Since they had heard about the legendary Oba-san, they flew him in and as soon as he landed, they took him to the factory. Oba-san immediately started to ask hundreds of questions. After some time, they asked him: “What do you think? Is this lean?” And he looked at them and he said: “Hmm, impossible to say”. And he continued to ask questions.

At lunch time they asked him again, he mumbled something in Japanese and then again: “It's impossible to say”. And he continued asking hundreds of questions.

By the end of the day, the CEO of the company came up to Oba-san and said: “Oba-san, we asked you to come here to give us a valid evaluation, to do an assessment of our operations and to give us some clear improvement suggestions. So I would like to have some kind of response from you. What do you say? Are we lean?”

And Oba-san looked at him and he said: “It's impossible to say, because I wasn't here yesterday”.

To build the capability to always improve

This story has really held a place in my heart since then, because I think it really captures what the Toyota Production System and operational excellence is all about. “It's impossible to say because I wasn't here yesterday.”

The way I interpret this story, is that this company, considered to be the number one within their industry, were performing high profitability, fantastic quality, and short lead times. They were the role model. But Oba-san said, it's not about the absolute level. It's about learning and continuous improvement.

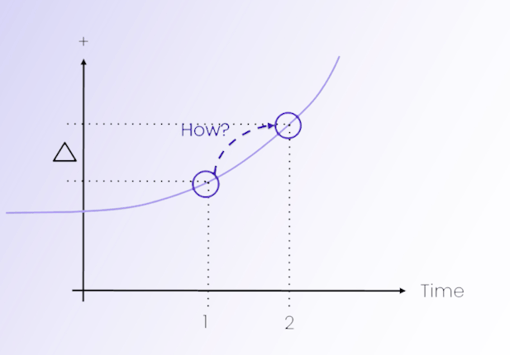

If he came to the factory at day one and saw how the company operated, and then came back day two, and saw that they had improved something. Whether it be quality, productivity, lead time, or safety. Or improved something within their operations - how they measure performance, manage their flows, or made sure that their resources are in the right state. That was what he was looking for, if they had learnt something.

So it's not about the absolute level, it's about taking small steps. To build a capability to always improve. It's not about finding the big fish. It's about teaching a capability how to fish.

How can you develop a capability where you always learn or implement continuous improvement? What is that capability all about?

You can't implement a happy customer

I had the opportunity to be with the number one Toyota researcher of all time, at least according to me, professor Takahiro Fujimoto. I got to know him in 2005, and he invited me to be a guest researcher at the University of Tokyo between 2006 and 2008.

He was the one who opened the doors to Toyota so people could research from outside and he said: “Toyota sustained competitive advantage stems from its capability building capability”. That is the essence and that is the same thing as Oba-san said.

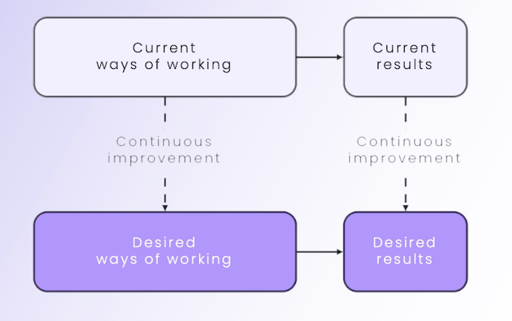

In any organization or company, we have our current ways of working, and these are our current results. Very simple, a snapshot of what our company looks like right now. All companies want to develop their ways of working so they can develop better results. And operational development is implementing continuous improvement so that we change our ways of working. And if we do that, then we can implement continuous improvement in our results.

We can't implement a happy customer or short lead times or high quality. That is impossible because it’s a lagging indicator. We need to look at the leading indicator if we want to change our results or our performance. We need to develop a capability of continuous improvement, to change our ways of working. Develop new routines and new tools to develop better ways of working. How can we collaborate better? How can we have smarter handovers? How can we align within goals? That is what continuous improvement is all about.

The capability building capability

And as a last reflection exercise, I want you to think, what does this mean? If the purpose is to improve, or if the purpose is to learn, how do we need to perform an activity?

Imagine that you have a customer meeting. One purpose is to “have a good customer meeting”. But what if the purpose is to “have a customer meeting in order to be able to deliver the customer meeting a little bit better next time”?

Or if you produce a product, and the purpose was “to produce the product so you could gain experience and knowledge, and the next time you produce that product, you could do it a little bit better”.

What does it take to get that mindset into your whole organization? The purpose is to learn. The purpose is to drive continuous improvement. The capability building capability.

Curious what this way of thinking could mean for your organisation?

If this story made you recognize challenges you have within the organization, just reach out and I'll be glad to share more from my work with continuous improvement.

And if you want to see how a digital system can support this in practice, you are welcome to take a closer look at our platform for continuous improvement.